Halving the Shaking Due to Long-Period Earthquake Ground Motion at Shinjuku Mitsui Building

Japan's First Rooftop-Installed Ultra-Large Vibration Control Device (Approx. 1,800 tons)

July 29, 2013

Mitsui Fudosan Co., Ltd., Kajima Corporation

Mitsui Fudosan Co., Ltd will install Japan's first tuned mass damper (TMD) ultra-large vibration control device (approx. 1,800 tons) at Shinjuku Mitsui Building in order to dramatically reduce shaking caused by long-period earthquake ground motion. Kajima Corporation will conduct the installation work, with work scheduled to begin in mid-August 2013 and to be completed at the end of April 2015.

The Shinjuku Mitsui Building fully satisfies current seismic performance standards. It is a highly safe structure that has obtained Ministerial approval for construction materials and building methods following a structural evaluation under the Building Standard Law. The initiative announced today aims to provide tenant office workers with additional reassurance by reinforcing the building's safety in the event of long-period earthquake ground motion in the future. This will be done by reducing the magnitude of building motion to the same level as that of a state-of-the-art skyscraper.

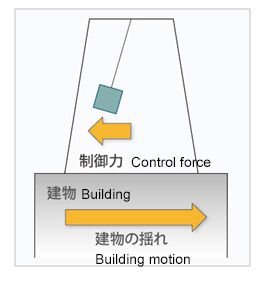

TMD refers to a pendulum-mass system that is conventionally used to control the wind-induced motion of skyscrapers. In this undertaking, Mitsui Fudosan and Kajima have developed and applied this technology for the first time in Japan to commercialize a vibration control device to control the seismic shaking of a skyscraper.

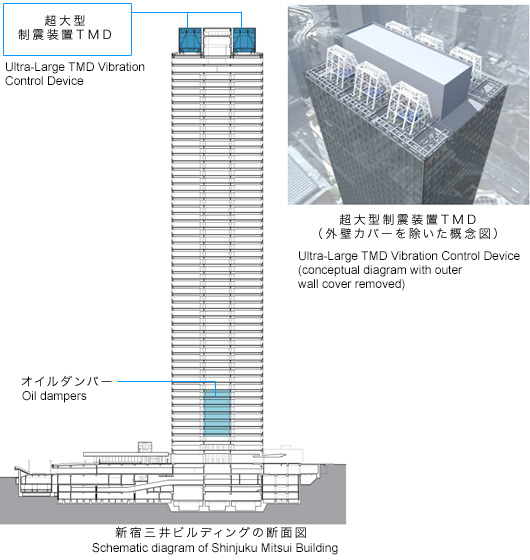

In the course of installing the vibration control device, the conventional method of installing oil dampers near the windows of an ordinary tenanted floor was considered. However, the method of installing the TMD on the rooftop was adopted because it greatly reduces the impact on the building's tenants. For example, the rooftop installation prevents the device from blocking the views from the building's windows and from reducing the building's effective floor area, in addition to eliminating the need for installation work within tenanted areas.

The benefits of introducing the vibration control device to the Shinjuku Mitsui Building are to substantially reduce the shaking that would be caused by long-period earthquake ground motion during a seismic event comparable to the Great East Japan Earthquake by half or more, while dampening the shaking as early as possible. In addition, Mitsui Fudosan and Kajima are jointly filing for a patent on a frame construction method for installing an ultra-large TMD vibration control device on a building rooftop.

* TMD: A device designed to control vibrations by attaching a mass to a building via a damper, and optimally tuning the natural frequency of the system.

Tenant companies, including those in the Shinjuku Mitsui Building, have an increasingly stronger need for safety and reassurance following the Great East Japan Earthquake, as well as for implementing business continuity planning (BCP) measures. Accordingly, Mitsui Fudosan is working to support those needs both in terms of physical infrastructure and services. For example, Mitsui Fudosan is strengthening renovation work that will upgrade the disaster readiness- and BCP-related functions of existing buildings to the same standards as new buildings (elevator seismic reinforcement work (class S, automated recovery equipment installation), work on extending the operating life and increasing the capacity of emergency power generators, etc.). We are also enhancing facility operation and management systems. The initiative announced today will allow measures to address long-period earthquake ground motion that are implemented at new buildings to also be implemented at existing buildings. As such, it will further strengthen the aforementioned measures. Looking ahead, Mitsui Fudosan will continue to embrace “WORKERS FIRST: offices where working people are number one” as the basic philosophy of its office building business, as it strives to ensure the highest level of safety and reassurance for all workers, while developing office buildings that are comfortable and convenient to work in.

As a pioneering skyscraper builder, Kajima has remained at the forefront of the industry by developing technologies particularly in the field of damping structures since the 1980s. In the initiative announced today, an ultra-large TMD for skyscrapers has been developed to address major earthquakes. Called “D3SKY (Dual-direction Dynamic Damper of Simple Kajima StYle),” the TMD is an effective solution that will help to alleviate concerns about long-period earthquake ground motion common to many existing skyscrapers. Looking ahead, Mitsui Fudosan will propose this TMD as one of many damping technologies it possesses. The TMD technology will be proposed for use in many seismic reinforcement projects for existing buildings, as well as for newly built skyscrapers. In doing so, Mitsui Fudosan will strive to help people lead safe, comfortable daily lives with peace of mind.

Outline of Vibration Control Device

Background and course of events leading to development

Tenant companies, including those in the Shinjuku Mitsui Building, have an increasingly stronger need for safety and reassurance following the Great East Japan Earthquake, as well as for implementing business continuity planning (BCP) measures. Accordingly, Mitsui Fudosan is working to support those needs both in terms of physical infrastructure and services. For example, Mitsui Fudosan is strengthening renovation work that will upgrade the disaster readiness- and BCP-related functions of existing buildings to the same standards as new buildings. We are also enhancing facility operation and management systems. The Shinjuku Mitsui Building is a highly safe structure that fully satisfies seismic performance standards based on a structural evaluation under the Building Standard Law. Following the Great East Japan Earthquake, Mitsui Fudosan and Kajima have considered ways to further increase the reassurance of the building's tenants.

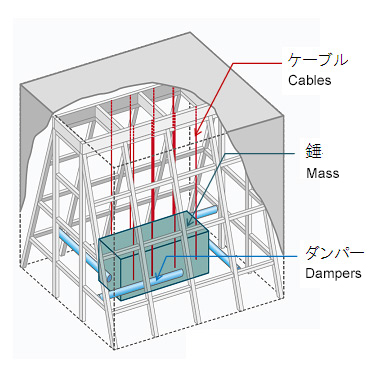

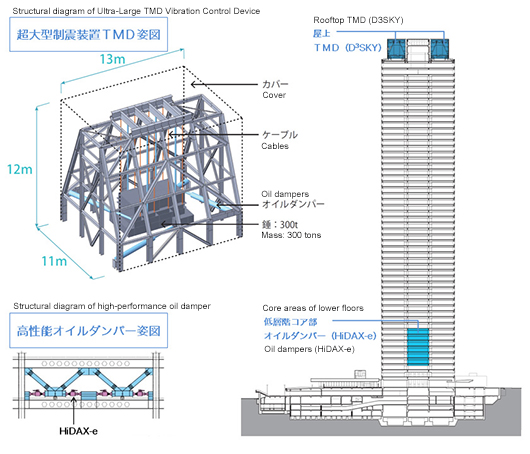

In the initiative announced today, we have commercialized a TMD (D3SKY) that makes it possible to dampen the motion of skyscrapers. This was achieved by the introducing the three technologies listed below. Each technology is based on the application of conventional TMD technology used to dampen the wind-induced motion of buildings. The newly introduced technologies will demonstrate a sufficient damping effect regardless of the magnitude and nature of the earthquake, which could range from an earthquake striking directly below the surface to long-period earthquake ground motion. The technologies will dramatically reduce damage to the existing frame and lower the amplitude and duration of building motion compared with what could be achieved by installing conventional damper braces.

- Mass support method: A cable-suspended mass support mechanism was adopted to satisfy the following two conditions: (1) To support the huge mass while tolerating large displacements in every direction; and (2) To ensure adequate durability against numerous repetitive motions.

- Deformity control oil damper: An oil damper with built-in deformity control functions has been introduced to satisfy the following two conditions: (1) To smoothly track the motion of the mass, which can move in 3 dimensions with an amplitude of nearly 2 m; (2) To smoothly decelerate the mass even in the event of a major earthquake exceeding design assumptions, thereby preventing any excessive displacement of the mass from damaging the TMD.

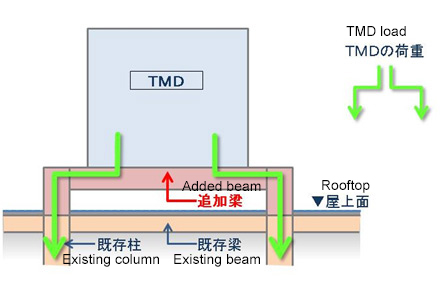

- Frame construction method: If a heavy structure is installed on the rooftop of an existing building, major reinforcement work was necessary due to the large load directly applied by the heavy structure to the existing beams of the top floor. In this building, new columns will be installed close to the existing columns supporting the existing beams, and a new beam with sufficient strength and stiffness will be laid between the new columns. This will transmit the heavy structure's load directly to the columns, allowing the tuned mass damper to be installed on the rooftop of the existing building.

TMD structural diagram

Schematic diagram of TMD

Frame construction method

Equipment Overview

- Ultra-Large TMD Vibration Control Device (D3SKY) x 6 units (mass: 1,800 tons)

Earthquake motions will be substantially dampened by absorbing the building's vibrational energy using the motion of a pendulum (mass: 300 tons). Six such pendulum units will be installed on the rooftop.

* D3SKY: Dual-direction Dynamic Damper of Simple Kajima stYle

- Earthquake motions will be dampened by controlling the amount of oil flow in the dampers according to the building's motion. 48 high-performance damper units will be installed in the core areas of the lower floors.

* HiDAX-e: High Damping system in the neXt generation eco

↑Click to Enlarge Image

↑Click to Enlarge Image

Effects and features of vibration control device installation work

Through the synergistic effects of the Ultra-Large TMD Vibration Control Device (D3SKY) and the high-performance oil dampers (HiDAX-e), the system will demonstrate the following performance:

- The system will drastically reduce the magnitude of various earthquake motions, ranging from an earthquake striking directly below the surface to long-period earthquake ground motion. It will have a particularly large damping effect with respect to long-period earthquake ground motion, drastically reducing motions by half or more. It will also show a significant effect in terms of reducing wind-induced motion caused by gales during major typhoons and other weather events.

- A single TMD (D3SKY) unit can control motion in two directions. It is a flexible system that can be adapted to buildings of varying heights and shapes by changing the weight of the mass and the number of TMD units installed.

- The system is not affected by power outages, because it does not use electricity.

Outline of construction work, Outline of the building

Outline of construction work

| Outline |

Install 6 units of TMD (D3SKY) (mass: 1,800 tons) on the rooftop

Install 48 units of high-performance oil dampers (HiDAX-e) within the core areas of lower floors |

| Construction period |

From mid-August, 2013 to the end of April, 2015 (planned) |

| Design and Supervision |

NIHON SEKKEI, Inc. |

| Design |

Kajima Corporation (First-class registered architect office) |

| Contractor |

Kajima Corporation

(This damping frame construction method is scheduled to obtain certification by the Minister of Land, Infrastructure, Transport and Tourism following a performance evaluation and assessment by The Building Center of Japan.) |

Overview of the Building

| Name |

Shinjuku Mitsui Building |

| Address |

2-1-1, Nishi-Shinjuku, Shinjuku-ku, Tokyo |

| Structure |

Steel structure (underground ferroconcrete/steel-reinforced concrete) |

| No. of floors |

55 floors above ground, 3 floors below ground; 210 m high |

| Applications |

Offices and retail stores |

| Completed |

September 1974 |

| Design |

NIHON SEKKEI (currently NIHON SEKKEI, Inc.)

Muto Institute of Structural Mechanics, Inc.

|

| Contractor |

Joint venture of Kajima Corporation and Mitsui Construction Co., Ltd. (currently Sumitomo Mitsui Construction Co., Ltd.) |