Japan’s Largest Plant Factory Producing 10,000 Vegetables Daily Starts Full-Scale Operation at Kashiwa-no-ha Smart City Plant Factory

June 5, 2014

Mirai Co., Ltd.

Mitsui Fudosan Co., Ltd.

Mirai Co., Ltd. (Mirai) and Mitsui Fudosan Co., Ltd. started full-scale operations of Japan’s largest plant factory, Kashiwa-no-ha GREEN ROOM 2, at Kashiwa-no-ha Smart City in June 2014.

These plant factories are highly productive multilevel cultivation facilities that enable the stable supply of vegetables. Horticultural technicians control compounds, enabling production of vegetables with superior functionality. The facility will produce at least 15 types of vegetable, including lettuce, green leaf, romaine, and red-leaf lettuce. It is Japan’s largest plant factory, capable of producing and shipping 10,000 plants daily.

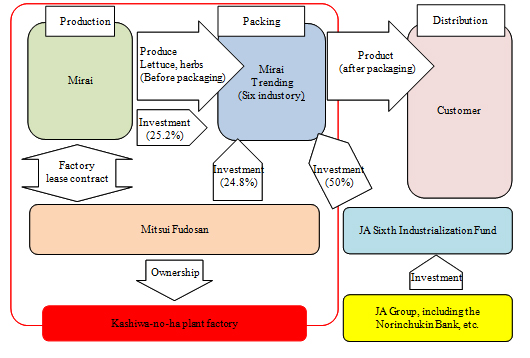

Kashiwa-no-ha Smart City is advancing the three initiatives of An Environmental-Symbiotic City, A City of Health and Longevity and A City of New Industry Creation, and this project is one aspect of A City of New Industry Creation that stipulates supporting startups in communities that utilizes Japanese technology. Mitsui Fudosan is the developer of the plant factory (of which Mitsui Home Co., Ltd. was contractor) and Mirai will operate the factory and produce vegetables. Those vegetables will be packed and shipped by Mirai Trading Co., Ltd., which is funded by Sixth Industrialization Fund set up by an alliance of the JA Group, its related organizations and the national government.

* Refer to project schematic on the following page

Mitsui Fudosan has opened incubation offices to move forward together on co-creation with startups possessing advanced technological capability at places like KOIL (Kashiwa-no-ha Open Innovation Lab) in Kashiwa-no-ha Campus City and LIAISON-STAGE Kasumigaseki in the Kasumigaseki Building Mirai has been a tenant since LIAISON-STAGE Kasumigaseki first opened. The plant factories are an initiative regarded as a representative case study for Mitsui Fudosan for not only providing offices but joining a startup to create a market.

Main Features of Kashiwa-no-ha GREEN ROOM 2, the Kashiwa-no-ha Smart City Plant Factory

- Cultivates vegetables without using agricultural chemicals in an environment closed to the outside air, enabling stable, year-round supply.

- Using multilevel cultivation beds allows for efficient vegetable production and harvesting in narrow spaces.

- Original cultivation technology software ensures vegetables produced with little bitterness, but high in nutritional value.

- Use of a new, standing-type packaging enhances cleanliness and lengthens preservation periods.

- Safety and productivity are enhanced by advanced airtightness and insulation in an expansive area created using wood construction techniques.

Plant Factory Initiatives at Kashiwa-no-ha

The smart city that Kashiwa-no-ha aims to become is not merely about being high-tech urban development using a smart grid to reduce energy use. It’s about urban development that creates an Environmental-Symbiotic City where residents can unconsciously reduce energy use while utilizing the rich natural environment. A City of Health and Longevity supports community food, exercise and participation with an underlying theme of preventative treatment in a rich and healthy lifestyle for children through to the elderly. A City of New Industry Creation seeks to advance community bonding to support the creation of technology startups and new industries that support future society.

Since the opening of the Center for Environment, Health and Field Sciences, Chiba University in 2003, Kashiwa-no-ha has continued researching and testing plant factories.

In October 2009, Chiba University, Mirai and Mitsui Fudosan installed a 6.6 m2 small-scale plant factory inside the LaLaport KASHIWANOHA shopping center. In May 2012, Chiba University set up a large-scale plant factory for demonstration testing on campus, and the Urban Plant Factory Consortium Kashiwa-no-ha Association was established as a consortium made up of academic institutions and companies involved in the research and development of plant factories with Mitsui Fudosan as its leader.

Furthermore, in September 2012, Chiba University, Mitsui Fudosan, Panasonic Corporation and Mirai developed a small household-use, network-style, wagon-type plant factory and conducted a test on vegetable cultivation for approximately one year using Kashiwa-no-ha area residents as monitors.

Social Background Requiring Plant Factories

Society’s interest in plant factories is growing in intensity due to issues such as food safety and security, rising vegetable prices due to climate change, greater interest in health, local production and local consumption and raising self-sufficiency rates. Plant factories have minimal risk of damage from the likes of climate, sickness or pests and plants are cultivated in an optimal environment, which enables safe and secure greens to be supplied with a stable quantity and quality while also addressing such societal issues as those mentioned above.

Project schematic (Details on previous page)

For further details, please refer to attachment PDF(976KB).