MFLP ICT LABO 2.0, an Interactive Logistics ICT Showroom, Opens on February 13

in Mitsui Fudosan Logistics Park Funabashi & GATE

Industry’s First Full-Automation Logistics Model* on Display;

Automates All Logistics Flows from Receiving to Shipping

February 13, 2020

Mitsui Fudosan Co., Ltd.

Key Points of This Press Release

- Interactive showroom MFLP ICT LABO 2.0 opens; industry’s first full-automation logistics model on display

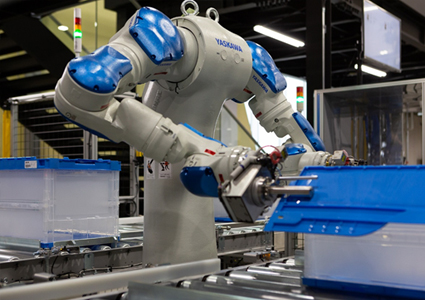

- Approx. 30 types of cutting-edge ICT devices on display, including first handling robot on permanent display in Japan

- Enhanced solution proposals using MFLP ICT LABO 2.0 for logistics industry issues like labor shortages

Tokyo, Japan, February 13, 2020―Mitsui Fudosan Co., Ltd., a leading global real estate company headquartered in Tokyo, announced today that it recently expanded and relocated MFLP ICT LABO of approx. 1,400 ft2 (approx. 130 m2) established in September 2017, and is opening MFLP ICT LABO 2.0 at MFLP Funabashi & GATE with approximately 10 times the floor area. This interactive logistics ICT showroom is the first in the industry* to display a full-automation logistics model for all processes from unloading products from truck containers to loading and with absolutely no manual operations.

Along with the full-automation logistics model, the showroom has approximately 30 types of cutting-edge logistics ICT devices from Japan and abroad, and tenant companies at Mitsui Fudosan logistics parks, and companies considering becoming tenants, are able to actually experience these devices firsthand.

For the logistics industry, which is facing labor shortages and other serious challenges, Mitsui Fudosan will utilize MFLP ICT LABO 2.0 to provide automation and labor-saving solutions for warehouse logistics and work to solve the issues of tenant companies and companies considering becoming tenants.

* The showroom represents the first attempt by a developer and operator of logistics parks to establish an interactive showroom focused on ICT.

MFLP ICT LABO 2.0 (1)

MFLP ICT LABO 2.0 (2)

MFLP ICT LABO 2.0 (3)

MFLP ICT LABO 2.0 (4)

■Mitsui Fudosan’s Logistics Park Business Initiatives to Date

Mitsui Fudosan entered the logistics park business on a full-fledged basis in April 2012 and established a logistics headquarters in April 2015. As a solutions partner for tenant companies, it works to connect various diverse people, goods and concepts to create value beyond existing demarcations.

In the environment surrounding the logistics industry, interest in automation is continuing to increase due to labor shortages and diversification in ICT products. In particular, against the backdrop of labor shortages, there is an urgent need for greater automation and better efficiency through the utilization of labor-saving measures and ICT in warehouse operations. At the same time, automation in logistics at present remains only partially developed, and many companies face the problem of not being able to promote automation for overall logistics operations.

In an effort to further strengthen solution proposal capabilities in line with customers in the logistics industry, through identifying issues at existing logistics parks, for example, Mitsui Fudosan has actively promoted development of advanced logistics facilities, and in September 2017, it established MFLP ICT LABO at Mitsui Fudosan Logistics Park Funabashi I in order to more fully identify the issues and needs of companies in the area of automation and labor-savings.

■MFLP ICT LABO 2.0 Features (1) First-in-Industry Full-Automation Logistics Model

To further strengthen automation and labor-saving solution sales, the showroom displays a full-automation logistics model that automates logistics flows from receiving to shipping. A warehouse management system has been built from the ground up to manage inventory and coordinate the processing capacities and launch speeds of the various devices. Visitors can see the flow of goods from the point products are brought in from truck containers to the point they are loaded, all without any manual operations.

■MFLP ICT LABO 2.0 Features (2) See All the Latest Logistics Devices at Japan’s First Permanent Display

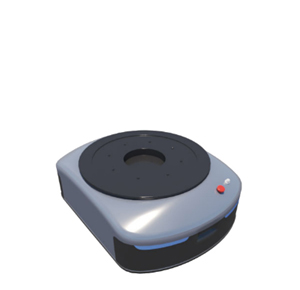

The various types of devices on display are the very latest in logistics ICT devices from Japan and abroad. They include the first permanent display in Japan of the Autonomous Mobile Robot (AMR) from Syrius Robotics Co., Ltd, a collaborative handling robot in which the robot performs work jointly with human workers, and the EVE rack transport robot from Geek+ K.K., which is on permanent display and can only be experienced at this showroom. All in all there are around 30 types of cutting-edge solutions on display. And, in the interactive solutions zone, visitors can actually use and operate devices and experience what they do firsthand.

■MFLP ICT LABO 2.0 Features (3) Logistics Consulting in Response to Tenant Company Needs

At MFLP ICT LABO established in September 2017, a total of over 250 companies visited, and more than ten companies went on to install logistics ICT devices displayed there. MFLP ICT LABO 2.0 also has a consulting room on site for Mitsui Fudosan to serve as a solutions partner in response to the needs of tenant companies, and not simply rent them space. By strengthening its solution proposals, Mitsui Fudosan is working to provide more customized solutions that flexibly solve customer issues, such as warehouse layout planning and cost-benefit calculations in connection with installation of logistics ICT devices.

<Main ICT Devices on Interactive Display at MFLP ICT LABO 2.0>

★ denotes new devices added at MFLP ICT LABO 2.0.

| 1. Auto Forklift from Mitsubishi Logisnext Co., Ltd.★ |

2. AGV (S-CART) from NIDEC-SHIMPO CORPORATION |

|---|---|

The Automated Guided Forklift system enables flexible conveyance, for applications from rack storage to flat stacking, without a human operator.

|

An automated carrier that takes the place of human operators and can flexibly accommodate layout changes and changes in usage location.

|

| 3. AutoStore from OKAMURA CORPORATION |

4. Picking Robot from Toshiba Infrastructure Systems & Solutions Corporation |

A human-friendly robot storage system, in which robots perform warehouse-in and -out operations for densely packed containers.

|

With this solution, a robot automatically recognizes and picks products from containers sent out and efficiently packs them in foldable containers.

|

| 5. Shuttle & Server from IHI Logistics & Machinery Corporation ★ |

6. EVE from Geek+ K.K ★ |

This automated warehouse system uses multiple high-speed shuttles to perform high-speed sorting by shipment and destination.

|

A major example of a goods-to-person (GTP) solution. A picking demonstration using this rack transport robot can only be experienced at MFLP ICT LABO 2.0.

|

| 7. Autonomous Mobile Robot (AMR) from Syrius Robotics Co., Ltd. (Shenzhen, China)★ |

8. SAI SOON from Nikon Systems Inc. ★ |

This collaborative autonomous mobile conveyor robot performs work jointly with human workers. It is easy to deploy and easy to operate, making it perfect for large warehouse operations like e-commerce warehouses in which the picking workload fluctuates.

|

Raises the efficiency of the ‘sa-sa-ge’ (photo-measure-write) process for e-commerce. When a photo is taken, the solution can automatically determine the dimensions and conduct product photo processing.

|

* Approximately 20 other varieties of cutting-edge solutions are also on display.

<MFLP ICT LABO 2.0 Facility Overview>

| Location | 2-3-1 Hamacho, Funabashi City, Chiba Prefecture (Inside MFLP Funabashi & GATE) |

|---|---|

| Access | 9 minutes on foot from Minami-Funabashi Station on the JR Keiyo Line |

| Scale | 1st floor: approx.11,000 ft2 (1,021 m2) 2nd floor: approx. 4,400 ft2 (404 m2) |

| Composition | Full-Automation Display Area Advanced Device Experience Area Consulting Room Theater Room |